The CNC router machine is an advanced tool that has revolutionized the manufacturing and woodworking industries. By combining precision, efficiency, and versatility, this machine has become an indispensable asset for many businesses and hobbyists. In this article, we will explore the features of CNC router machine, their applications, and how they compare to other CNC woodworking machines.

What is a CNC Router Machine?

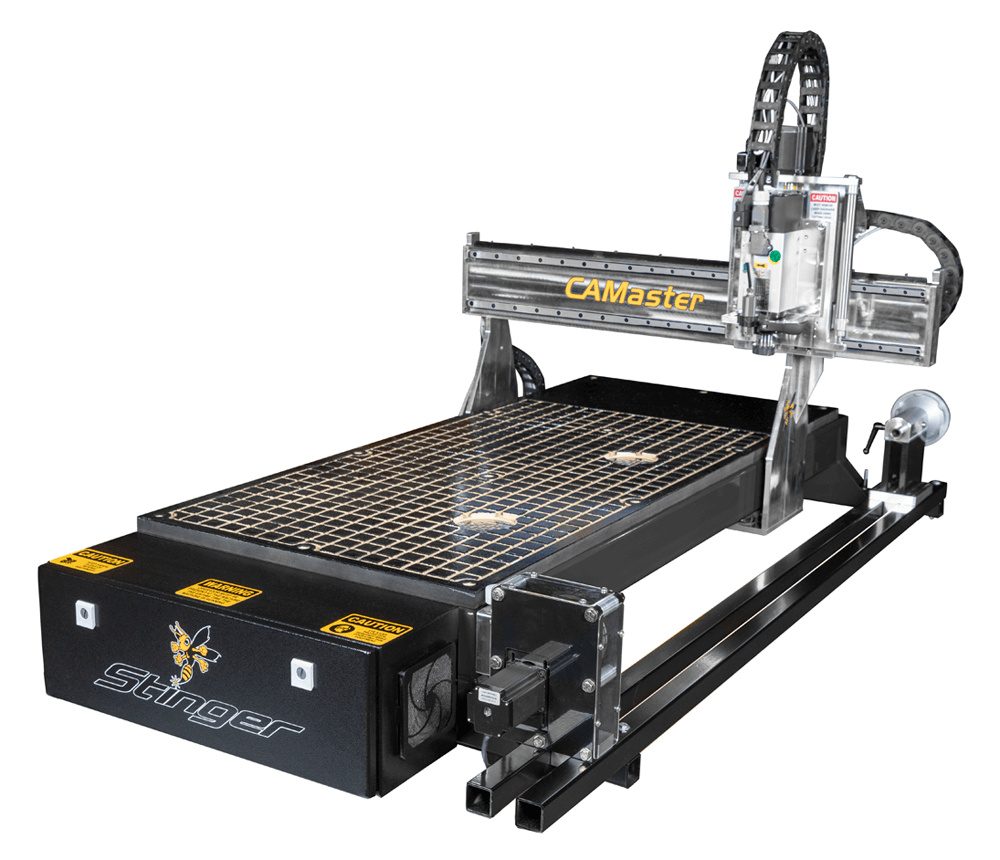

A CNC router machine, or Computer Numerical Control router, is a cutting tool that uses computer programming to control its movements and operations. This technology allows for precise cutting, carving, and shaping of various materials, including wood, metal, plastic, and composites. Unlike manual routers, CNC routers operate autonomously, guided by digital instructions that ensure accuracy and consistency.

Key Features of CNC Router Machines

1. Precision and Accuracy

One of the most significant advantages of CNC router machines is their ability to produce highly accurate and repeatable cuts. The machine’s computer-controlled movements ensure that each cut adheres to the exact specifications of the design, reducing human error and material waste.

2. Versatility

CNC routers are known for their versatility. They can handle a wide range of materials and perform various tasks, including engraving, inlaying, and 3D carving. This makes them suitable for diverse applications, from intricate woodworking projects to complex metalwork.

3. Automation

Automation is a key feature of CNC router machines. Once programmed, the machine can operate continuously without the need for manual intervention. This not only speeds up the production process but also allows for consistent quality across multiple pieces.

4. Customization

With CNC router machines, customization is straightforward. Users can create intricate designs and modifications to suit specific project requirements. The machine’s flexibility allows for easy adjustments, making it ideal for both bespoke and mass-produced items.

Applications of CNC Router Machines

1. Woodworking

In the woodworking industry, CNC router machines are widely used for creating detailed carvings, furniture components, and cabinetry. Their ability to work with large sheets of wood and produce precise cuts makes them a valuable tool for craftsmen and manufacturers alike.

2. Signmaking

CNC routers are also popular in the signmaking industry. They can carve out letters, logos, and intricate designs on various substrates, including wood, acrylic, and metal. This capability allows for the production of high-quality, custom signage with consistent results.

3. Prototyping

For designers and engineers, CNC router machines are essential for creating prototypes. The ability to quickly produce accurate models and test designs helps streamline the development process and bring ideas to life more efficiently.

4. Manufacturing

In larger manufacturing settings, CNC routers are used to create parts and components with high precision. Their efficiency and automation capabilities make them a cornerstone of modern production lines, ensuring both speed and quality.

Comparison to Other CNC Woodworking Machines

While CNC router machines are versatile and efficient, they are just one type of CNC woodworking machine. Other machines, such as CNC mills and lathes, offer different capabilities. CNC mills are ideal for more complex cutting and shaping tasks, while lathes are better suited for turning operations. Each machine has its strengths, and the choice depends on the specific needs of the project.

Conclusion

The CNC router machine stands out as a powerful tool in the realm of woodworking and manufacturing. Its precision, versatility, and automation capabilities make it an invaluable asset for a wide range of applications. Whether you are a hobbyist crafting unique items or a manufacturer producing components at scale, a CNC router machine can significantly enhance your efficiency and output. By understanding its features and applications, you can make informed decisions on how to integrate this technology into your work processes.