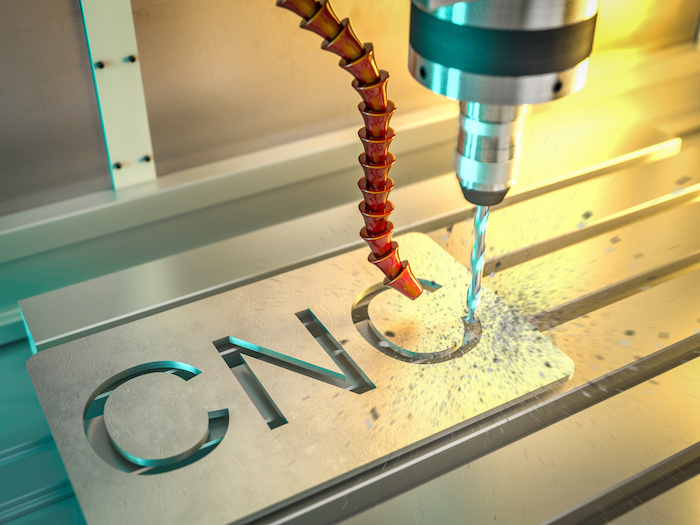

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry by providing precision, efficiency, and versatility. These machines are controlled by a computer and are capable of performing a variety of tasks, including cutting, milling, drilling, and engraving. For businesses looking to enhance their production capabilities, investing in CNC machines can be a game-changer.

Benefits of CNC Machines

Precision and Accuracy

CNC machines are renowned for their precision and accuracy. They can execute complex designs with minimal human error, ensuring consistent quality across all produced parts. This level of precision is particularly beneficial for industries where tight tolerances are crucial, such as aerospace and medical device manufacturing.

Increased Efficiency

By automating the manufacturing process, CNC machines significantly increase efficiency. They can operate continuously with minimal supervision, reducing downtime and increasing production rates. This is especially advantageous for large-scale manufacturing operations that require high output.

Versatility

CNC machines are incredibly versatile and can be used to produce a wide range of products. From simple cuts to intricate designs, CNC machines can handle various materials, including wood, metal, plastic, and composites. This versatility makes them ideal for businesses in diverse industries.

Cost-Effectiveness

While the initial investment in CNC machines can be substantial, the long-term cost savings are significant. Reduced labor costs, decreased material waste, and increased production speeds contribute to overall cost-effectiveness. Additionally, the durability and longevity of CNC machines mean they can serve a business for many years.

Understanding 5×10 CNC Routers

What is a 5×10 CNC Router?

A 5×10 CNC router is a specific type of CNC machine with a working area of 5 feet by 10 feet. This size is particularly popular in industries such as woodworking, sign making, and furniture manufacturing. The larger working area allows for the creation of bigger pieces without the need for repositioning, which enhances both efficiency and accuracy.

Applications of 5×10 CNC Routers

Woodworking

In the woodworking industry, 5×10 CNC routers are used to create custom furniture, cabinetry, and decorative pieces. Their ability to cut intricate designs with high precision makes them invaluable for producing high-quality wood products.

Sign Making

Sign makers benefit from the large working area of 5×10 CNC routers, which allows for the production of large signs in a single pass. These routers can cut various materials used in sign making, including wood, acrylic, and aluminum, providing versatility in design and application.

Furniture Manufacturing

For furniture manufacturers, 5×10 CNC routers streamline the production process. They can efficiently cut and shape large panels of wood, enabling the creation of complex furniture designs. This not only speeds up production but also ensures consistency in the final product.

Key Features of 5×10 CNC Routers

Large Working Area

The 5×10 working area is one of the most significant features of these routers. It provides ample space for larger projects, reducing the need for material repositioning and thereby saving time and improving accuracy.

High-Speed Spindle

Many 5×10 CNC routers come equipped with high-speed spindles, which enhance cutting speed and precision. This feature is particularly useful for detailed work, as it allows for smoother and more accurate cuts.

Advanced Control Systems

Modern 5×10 CNC routers are equipped with advanced control systems that provide greater control over the cutting process. These systems allow operators to program complex designs and monitor the machine’s performance in real-time, ensuring optimal results.

Finding CNC Machines for Sale

New vs. Used CNC Machines

New CNC Machines

Purchasing a new CNC machine comes with several advantages, including the latest technology, warranties, and manufacturer support. New machines are less likely to require immediate repairs and typically offer the most advanced features available.

Used CNC Machines

For businesses on a budget, used CNC machines can be a viable option. While they may not have the latest features, many used machines are still highly functional and can provide excellent value. It’s important to thoroughly inspect used machines for any signs of wear and ensure they have been well-maintained.

Factors to Consider When Buying a CNC Machine

Budget

Determine your budget before starting your search for a CNC machine. This will help narrow down your options and ensure you find a machine that meets your financial constraints.

Specific Needs

Consider the specific needs of your business. What materials will you be working with? What types of products will you be producing? Answering these questions will help you choose a CNC machine that is well-suited to your requirements.

Machine Specifications

Pay attention to the specifications of the CNC machines you are considering. Key specifications include working area size, spindle speed, control system, and compatibility with various materials. Make sure the machine you choose can handle your intended applications.

Vendor Reputation

Research the reputation of the vendors you are considering. Look for reviews and testimonials from other customers to ensure you are buying from a reputable source. A reliable vendor will provide support and service for the machine, which is crucial for long-term success.

Where to Find CNC Machines for Sale

Online Marketplaces

Online marketplaces are a popular option for finding CNC machines for sale. Websites dedicated to industrial equipment often have extensive listings of both new and used machines. These platforms allow you to compare prices, features, and seller reputations.

Auctions

Industrial auctions can be a great place to find deals on CNC machines. Many companies liquidate their assets through auctions, providing opportunities to purchase high-quality machines at lower prices. However, it’s important to thoroughly inspect the machines before bidding.

Manufacturer Websites

Many CNC machine manufacturers sell their products directly through their websites. Buying directly from the manufacturer can provide peace of mind, as you are assured of the machine’s quality and can often take advantage of warranties and support services.

Conclusion

Investing in a CNC machine, particularly a 5×10 CNC router, can significantly enhance your business’s production capabilities. These machines offer precision, efficiency, and versatility, making them ideal for a wide range of applications. Whether you choose to buy new or used, it’s important to carefully consider your needs, budget, and the machine’s specifications. With the right CNC machine, you can take your manufacturing processes to the next level, ensuring high-quality output and increased productivity.