In the competitive world of automotive manufacturing, precision and quality are non-negotiable. Every vehicle is made up of thousands of components, each of which must function flawlessly to ensure the safety, performance, and durability of the final product. This is where automotive parts sorting & inspection services become crucial. These services guarantee that every part used in the production process meets stringent quality standards, minimizing the risk of defects and failures. Effective Inspection Services are vital to maintaining quality control throughout the supply chain and protecting both manufacturers and consumers from costly errors.

The Importance of Automotive Parts Sorting & Inspection

With such a wide range of parts involved in building a car, from engine components to electronic systems, maintaining consistent quality is a major challenge. Even a minor flaw in a component can lead to significant issues, from vehicle malfunctions to safety hazards. By utilizing Automotive Parts Sorting & Inspection Services, manufacturers can detect defective parts early, preventing them from being installed in vehicles and reducing the risk of recalls or accidents.

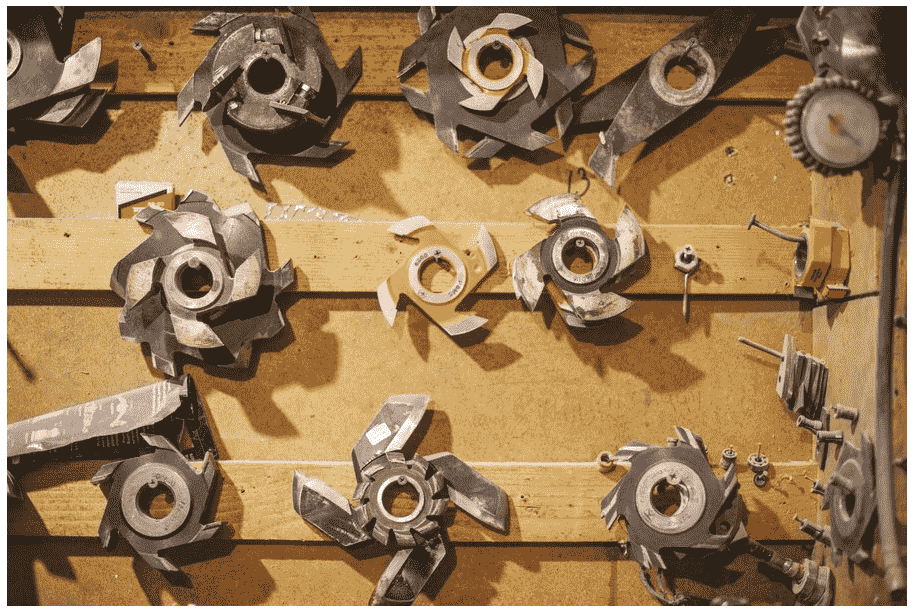

Automotive Parts Sorting & Inspection Services involve carefully examining each part to identify any imperfections or deviations from specifications. Sorting is the process of separating compliant parts from defective ones, ensuring that only high-quality components make it to the assembly line. Inspection Services, on the other hand, involve a detailed analysis of each part’s physical characteristics, dimensions, and overall integrity.

Types of Inspection Services

There are several different methods of Inspection Services employed in the automotive industry, each tailored to specific components and quality control needs.

- Visual Inspection: This is the most straightforward form of inspection, where parts are visually checked for surface-level defects such as cracks, dents, or deformities. While it may seem basic, visual inspection is an essential first step in catching obvious issues before they cause further problems.

- Dimensional Inspection: Precision is a key factor in the automotive industry, and Dimensional Inspection Services ensure that parts meet exact size and shape requirements. Using advanced measuring tools such as calipers, micrometers, and coordinate measuring machines (CMM), technicians verify that each part conforms to strict tolerances. This ensures that parts fit together seamlessly during assembly.

- Non-Destructive Testing (NDT): Some defects, such as internal cracks or voids, cannot be detected through visual or dimensional inspection. This is where Non-Destructive Inspection Services come into play. Using techniques like ultrasonic testing, X-rays, and magnetic particle testing, inspectors can identify hidden flaws without damaging the part. NDT is especially important for critical components like engine blocks or suspension systems that are subjected to high stress.

- Functional Testing: In some cases, parts need to be tested in real-world conditions to ensure they work as expected. Functional testing is used to verify that components like brakes, gears, and sensors perform their intended functions under specific operating conditions. This ensures that every part will function properly once integrated into a vehicle.

Benefits of Outsourcing Automotive Parts Sorting & Inspection Services

Many automotive manufacturers choose to outsource their Automotive Parts Sorting & Inspection Services to specialized companies that focus solely on quality control. Outsourcing these services offers several advantages:

- Expertise: Third-party inspection services providers have specialized knowledge and experience in identifying and addressing quality issues, ensuring a higher level of accuracy in the inspection process.

- Cost Efficiency: By outsourcing, manufacturers can avoid the need to invest in expensive inspection equipment and training programs. This helps reduce operational costs while maintaining high-quality standards.

- Flexibility: Outsourced providers offer scalable solutions, allowing manufacturers to adjust their inspection requirements based on production volume and demand.

- Time Savings: Outsourcing Inspection Services allows manufacturers to focus on core activities, such as design and production, while ensuring that quality control is handled by experts.

Conclusion

In the automotive industry, quality control is essential to maintaining safety, performance, and customer satisfaction. Automotive Parts Sorting & Inspection Services are a critical part of this process, helping manufacturers detect defects early and ensure that only the best parts are used in vehicle production. By utilizing advanced Inspection Services such as visual inspection, dimensional analysis, non-destructive testing, and functional testing, manufacturers can maintain high standards and avoid costly errors. For many companies, outsourcing these services to specialized providers offers a cost-effective way to enhance quality control, streamline operations, and ultimately deliver safer and more reliable vehicles.